- Our Company

- Our business

- Investors

- Press-Room

- Sustainability

Thermal and hydro power plants are operated in strict compliance with the laws and regulatory technical standards in industrial safety of hazardous production facilities and security of hydraulic structures at all Company’s facilities.

RusHydro Group companies are backbone and have a significant effect on the condition of industrial and energy safety of the sector ensuring reliable and smooth power supply of consumers.

Reliable and safe operation of energy facilities is a strategic transient priority for the Company and is one of the ten most significant aspects. Taking into account potential risks and possible impacts, this aspect has a substantial economic, environmental and social significance for a wide range of stakeholders including production and industrial personnel of the Company and local communities.

Reliability means functionality of equipment and hydraulic structures during the entire service life with the initially defined parameters maintained.

Safety means ensuring conditions free from unacceptable risk related with the harm to health, property of natural persons and entities, state and municipal property and environment.

RusHydro projects to increase safety level of hydraulic structures

The largest projects completed in 2017-2018 and intended to improve safety of the hydraulic structures are as follows:

Ongoing activities:

Safety and reliability management system of hydraulic structures and equipment

RusHydro internal commissions together with representatives of regional authorities of the Ministry of Emergency Situations annually inspect HPP readiness for operation in the autumn-winter period and issue respective certificates.

In 2017, all Company’s HPP received readiness certificates for the autumn-winter period of 2017-2018.

Since 2018, the level of readiness of RusHydro energy facilities for operation during heating (autumn-winter) season has been evaluated as an all-year-round monitoring of readiness. Readiness monitoring includes formation and approval of initial data for evaluating the compliance with readiness indicators and conditions of RusHydro Group energy facilities for operation in the heating season as well as an inspection calculation of readiness indexes of RusHydro Group energy facilities based on the reference data as per the Methodology of Evaluating Readiness of Energy Faculties for Operation in the Heating Season approved by the Decree of Minenergo No. 1233 as of December 27, 2017.

Order No. 515 as of August 8, 2017 updated and enacted the Regulation for Safety and Reliability Management System for Hydraulic Structures and Equipment of RusHydro Hydro Power Plants.

System principles:

Major processes of the System:

In terms of evaluation of technical condition of equipment, order No. 913 dated December 25, 2017 enacted the Methodology for Evaluation of Technical Condition of Primary Process Equipment and Power Lines of Power Stations and Networks approved by the order of Minenergo No. 676 dated July 20, 2017.

Production monitoring

A mandatory condition of faultless operation of energy facilities is production monitoring of compliance with industrial safety regulations. Organization of timely maintenance, planned repairs, modernization of equipment, buildings, structures and utilities in energy units has a substantial effect on the quality of production and process facilities, extension of the service life and faultless operation of existing assets.

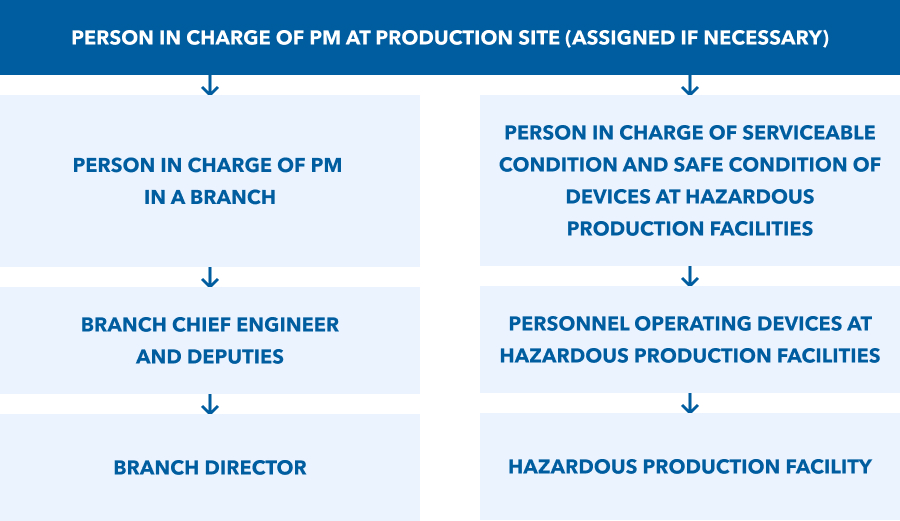

Typical structure of production monitoring in RusHydro branches

Monitoring and condition evaluation of RusHydro hydraulic structures

Condition monitoring of hydraulic structures (HS) is provided using standard monitoring systems installed at the stage of construction and modernized during the operation.

Monitoring of HS parameters

|

On concrete dams |

On soil dams |

In areas adjacent to HS |

|

|

|

RusHydro’s HS safety oversight system

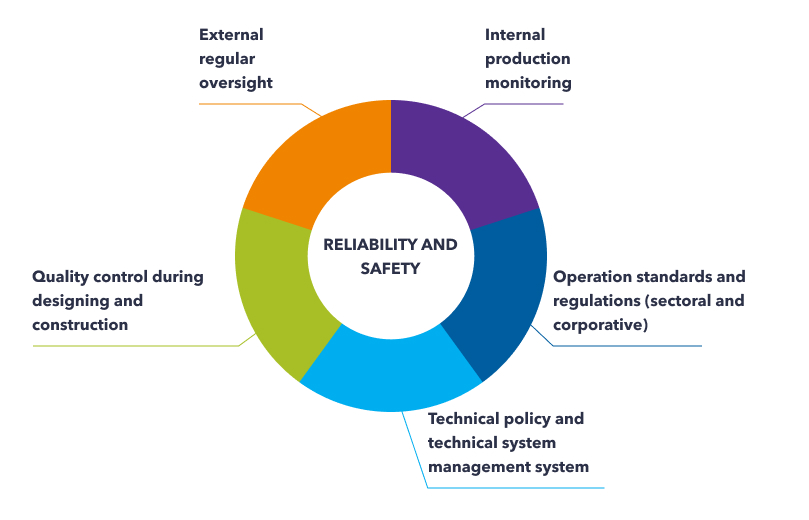

Efficiency of operation safety and reliability oversight of the existing assets is achieved by the double monitoring system: internal system by means of production monitoring over the compliance with industrial and professional safety at hazardous production facilities, and external system provided by state surveillance authorities.

The oversight system includes:

Mechanisms ensuring operation and safety reliability of the facilities.

Natural disaster and emergency prevention and response system

All RusHydro Group facilities operating HSs have:

Emergency prevention and response measures

Quality management during designing

The quality level of operating characteristics of equipment and HPP structures is defined at the stage of designing and is mainly defined by the quality of processes and design output. RusHydro facilities are designed by the research and design company and the design documentation is subject to the state expert examination. RusHydro and companies of RusHydro Group act as customers (developers).

Based on the R&D institute of RusHydro Group, a whole range of R&D activities is carried out for designing hydraulic, energetic, industrial and civil construction and water facilities. Moreover, activities are undertaken to diagnose and extend the service life of existing facilities, develop technologies to improve operating characteristics of hydraulic structures and HPP equipment in order to improve reliability and safety of energy facilities and reduce their environmental impact.

All project institutes of RusHydro Group implement quality standards and implement the quality management system from the beginning of hydro power project development to commissioning. The process and design output monitoring system is governed by local regulations developed under the RusHydro Technical Policy, branch and international technical standards.

Moreover, the quality of projects is ensured by advanced methods and technologies, state-of-the-art materials and structures, and scheduled measures to reduce negative effects and compensation measures at the construction stage.

A mandatory condition of project approval at the initiation stage is the analysis of the environmental impact of a capital construction facility. The primary part of the designing stage is to develop measures during construction and operation periods.

Quality management during construction

Quality control during construction and assembly works is provided for:

Quality control:

Audit results of quality management systems, certification results of quality management systems for compliance with international standards.

The following RusHydro controlled organizations have ISO:9001:2015 certificates: OJSC Far East Generation Company, OJSC Far East Distribution Grid Company, All-Russian Vedeneev Hydraulic Engineering Research Institute, JSC Scientific and Research Institute of Energy Structures, JSC Zhuk Institute Hydroproject, JSC Lenhydroproject, JSC Mosoblhydroproject, JSC Hydroremont-VCC, JSC ChirkeiGESstroi, PJSC Yakutskenergo.

RusHydro quality management regulation has been developed based on: ISO:9001:2015. RusHydro has not certified the quality management system in accordance with international standards.

RusHydro quality management system is governed by the following documents:

Regulation on RusHydro production activity quality management system is developed in accordance with the methodology instructions of the Federal Agency for Inventory Management and the quality management system regulation. The regulation provides quality control – systematic oversight and control over compliance with quality process using own resources and contractors in construction, technical reconstruction and modernization and their results as part of expert and surveillance activity: expert examinations of activity results; technical audits, construction control; oversight of the equipment and materials manufacturing at the manufacturers; technical oversight of surveys, etc.

Information on technical audits by RusHydro

RusHydro has developed the Regulation on technical audits of the Company’s energy facilities approved by RusHydro Order No. 357 dated May 14, 2020.

Primary goals of technical audit are collection, systematization, analysis, comprehensive evaluation of information received during inspection which results in opinions, recommendations and proposals of audits for achieving the compliance of production assets of Company’s energy facilities with established regulatory acts of the Russian Federation in the field of occupational health, industrial, fire and environmental safety, operating rules and regulations (ORR), and requirements of the Technical and Environmental Policy of RusHydro Group.

RusHydro Decree No. 487r dated December 10, 2020 approved the schedule and plan of technical audits in 2021. According to the plan, technical audits of production activities are undertaken in RusHydro branches and controlled organizations in the following areas: